Engravings of the Deep

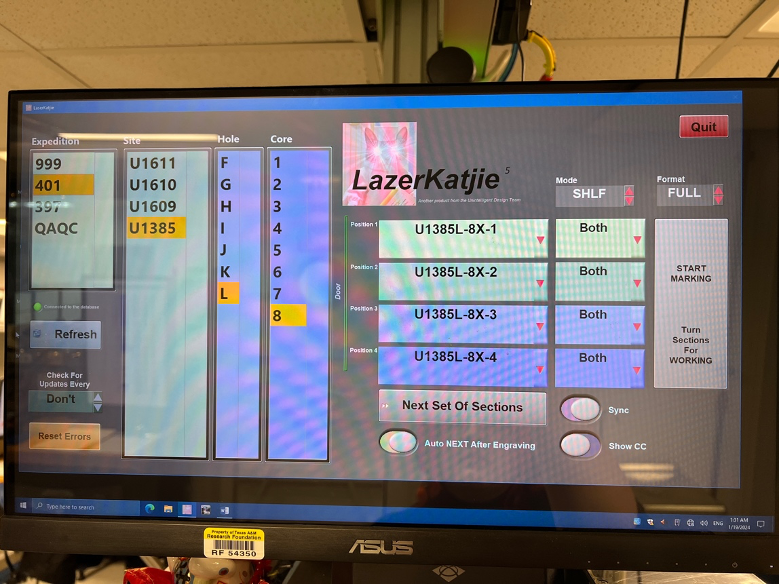

Every section of core the JOIDES Resolution (JR) brings up to the surface is meticulously labeled and organized with detailed stickers, wrapped in thick clear tape. Each sticker lists the expedition, site, hole, and core section. If this system fails, we also engrave the core liner itself using our onboard laser engraver, the LaserKatjie 3.0! When engraving a core liner, it is a few simple clicks to carve the plastic with the correct label.

“You used to have to hand engrave the core liner with a hand Dremel. It still hangs next to the machine, just in case,” said Zenon Mateo, Expedition 401’s Laboratory Specialist. Like most things on the JR these days, the laser engraver is a smooth running, easy to follow system.

The laser engraver does more than just label our cores, it also helps make great souvenirs. The MarkingBuilder Program allows for custom logos to be engraved onto nearly any surface. For instance, our core liners are cylinders with a 70mm diameter, but it’s also possible to engrave wooden boxes or even metal.

This expedition several of our technicians worked to engrave our expedition patch logo on extra core liner. The expedition logo is round and they are engraving on a round surface which causes warping, so adjustments to the design need to be made. The laser program has a known area that displays as a grid onto the surface you want to engrave. You can adjust power and speed which effect how deep the laser engraves the surface. It requires a lot of trial and error, but thankfully we have lots of core liner trimming to practice with.

This expedition several of our technicians worked to engrave our expedition patch logo on extra core liner. The expedition logo is round and they are engraving on a round surface which causes warping, so adjustments to the design need to be made. The laser program has a known area that displays as a grid onto the surface you want to engrave. You can adjust power and speed which effect how deep the laser engraves the surface. It requires a lot of trial and error, but thankfully we have lots of core liner trimming to practice with.

The engraver uses a carbon dioxide laser which vaporizes a surface without damaging the structure underneath. “It’s a class 4 laser and is very dangerous if left open,” said Mateo.

The laser itself can damage your eyes, so it has built in safety glass with a green tint allowing the technicians to watch their masterpieces come to life. It also has a safety interlock system, preventing firing of the laser when the door is open.

If you have something you wish to engrave and the time to take the IODP safety courses, you can engrave nearly anything while aboard the JOIDES Resolution, such as an official IODP water bottle. Additionally, our core liner pieces create a great way to transport shrunken cups with style. Two souvenirs in one.