What do Soda Cans, Resistivity, and Drilling have to do with each other?

“Turns out soda cans and core liners have the same diameter” That was the start of a very interesting, but useful DIY experiment out here on the Tyrrhenian Sea.

Watch the movie to see the process of testing the soda can meter and/or read below for a quick summary.

Clay Furman is the Schlumberger Logging Engineer in charge of helping the science crew with downhole logging. When the borehole is finished being drilled for core collection, scientists will want to take measurements of the actual cored geological formations in the borehole. They can correlate that data to the data collected in the core as a way to close any gaps of information. Clay who is an expert in how to build, use, and run the logging tools, is contracted out from Schlumberger so there is only one of him on board trained to use the tools. One of the tools he deploys reads the electrical resistivity geological formations through the borehole walls. Electrical Resistivity is measuring the materials resistance to an electrical current moving through it. Plus, resistivity plays an useful role in identifying both the chemical and minerology make up of the surrounding fluids and geological materials. This information can be the building blocks to answering questions about historical climates and environments. These kinds of details are fascinating to Philippe Pezard, the downhole logging specialist, who spends time reading the output of the 4+ logging tools used during expedition.

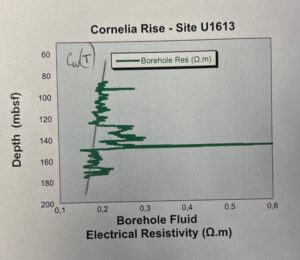

After logging one of our drilling sites, Philippe noticed that in the logging results there was an area of higher resistivity than the rest of the borehole. This was interesting because the cores did not have a similar increase. So it begs the question, what made it get that high?

One notable fact is that we use drilling fluid when coring. During drilling operations we use drilling fluids to help flush out the borehole of cuttings that get generated as we core. But if the cuttings aren’t flushing out of the borehole as fast as we need, we will switch to drilling mud which is seawater mixed in with a high viscosity mud. Soon after seeing the results, Philippe decided to determine the resistivity of the drilling mud and enlisted the help of Clay. It was theorized that the drilling mud was giving off that resistivity measurement rather than that of seawater.

To clarify, drilling fluid is used to flush out the drilling cuttings throughout the process of drilling to avoid the drill pipe from getting stuck during operations. Since the resistivity logging tool sends an electrical current out from the tool into the borehole wall and back, the resistivity of any material both liquid and solid will be recorded. If the drilling fluid was not flushed out before the logging tools were sent down, we would also be recording that drilling fluid resistivity.

To determine if the theory was correct, Clay built a DIY resistivity meter out of soda cans. Then took the data back to Philippe to compare it to the results shown above. Turns out, the spike in resistivity was due to a certain amount of drilling mud that got stuck in that part of the borehole!