My Journey to the Mud Room

During transit there is not a lot of excitement in the lab, so I took a quick trip into the JR’s mud room. It is more interesting that you might think!

Why doesthe JR store mud onboard? Because it is an integral part of the drilling process.

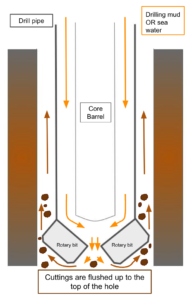

The drill is constantly breaking material away from the sides of the hole with pressure from the drill string and these cuttings can build up and jam the drill. Pumping sea water down the drill pipe is the most obvious way to keep the cuttings from jamming the drill and the JR uses seawater for this purpose more than 99% of the time. Think about how you can dig a hole with a hose. The water under pressure will move sediment out of the way. This is similar to how the JR pumps water down the drill pipe. This water will both lubricate and cool the drill bit as well as clear the cuttings from the hole.

The mud room is a large square with the four walls of the moon pool in the middle. Six separate storage tanks under the floor can hold various types of drilling mud. The JR occasionally uses Sepiolite which is much more viscous than sea water and will help sweep the hole by lifting the cuttings more efficiently. Another type of mud that is onboard the JR, but is rarely used, is Barite. This mud is really heavy, 10.5lbs/gal compared to sea water which is 8.3lbs/gal, and would help keep any hydrocarbons down in the formation. Hydrocarbons that travel to surface rapidly expand and become a problem. The science team

onboard the JR constantly monitors for hydrocarbons even though they choose their drill sites so as to avoid any hydrocarbon rich areas.

The dry mud is stored onboard and mixed with sea water when it is needed. The mixture in the tank gets circulated constantly so that the mud stays in suspension. When the hole needs to be swept, the mud gets pumped from the tanks through a three-piston system. Because the flow of the mud is important, a Nitrogen bladder is used to smooth out and create a laminar flow of the mud. It is this flow that will get pumped up to the top of the drilling machine and then go into the drill pipe at an appropriate pressure which will vary depending on many factors about the operation.