A unique way to install a reentry system at Site U1440B

Since we have already drilled a hole at Site U1440 (approximately 20 meters from where we are now) and collected sediment cores from that hole up until we hit hard rock, we started our second hole in a whole new way. Because this hole will be used to obtain cores from deeper depths we need to ‘case’ the hole to keep it stable. We also need to be able to re enter it several times.

To achieve these goals, we are using a new, faster method to install the reentry system using an underreamer and mud motor. The underreamer has hydraulic “arms” that open up and spin once under pressure, and aim jets of water at the front of the drill bit to help drill through the sediment and remove the debris.

Following the underreamer is the casing. The casing is a long steel tube that keeps the sides of the sediment from caving in. The casing keeps the hole diameter narrow to maintain the velocity of sea water or drilling mud (used to remove small sand-grain-size rock particles from the hole) but is wide enough to allow the underreamer and drill bit to pass through, and drill out the sediment ahead of it.

The casing string can have different diameters that can be telescoped down from the top of the hole. (The narrowest diameter is at the bottom; the wider diameter is at the top.) Depending on the depth of sediment that needs to be shored up, you may need to use multiple diameters of casing. Here, we are using two different diameters of casing to make up the 99-meter casing string: 10 3/4″ and 16″ casing with a transition piece connecting the two pipe diameters.

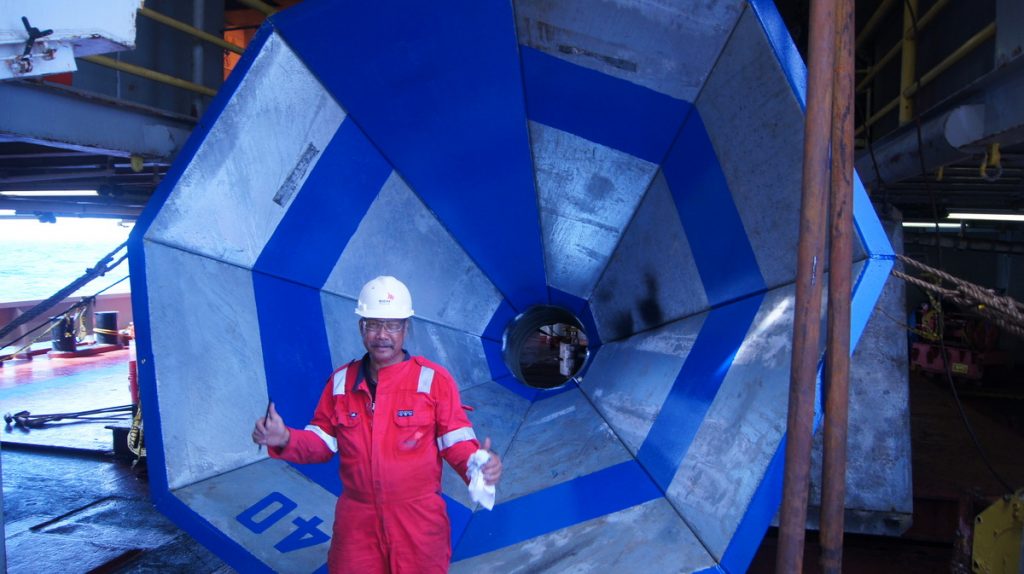

Finally, above all of this is the reentry cone that will allow us to get back into the hole at 4,775 m water depth. As new hole is created by the underreamer and drill bit, the casing advances deeper into the sediment until the reentry cone settles on the seafloor. At the same time, sediment collapses around the casing and keeps it from moving.

Once the reentry system is in place, the underreamer assembly has to come up before we can start coring. The drill string is pulled all the way back to the ship and a new drill string is assembled with a rotary core barrel (RCB) bit that can drill through hard rock. The drill string is then lowered back down to 4,775 meters to the reentry cone.

Meanwhile, the ship is moving every which way due to wind, waves, swells, etc. The reentry cone (along with a camera to help us see and the dynamic positioning system that keeps us in place) will aid in getting the drill string back into the hole. Imagine trying to hit a 16” hole in 4,775 meters of water without the aid of the reentry cone; it’s a little like threading a spaghetti noodle into a straw from the top of a tall building. Once the RCB bit reaches the bottom of the hole (where the end of the casing is), coring can truly begin.

Thanks to the ingenuity of the drilling operations team, we can drill a hole, case it and put in a reentry cone in one step. This action gives us FIVE extra days that could be used to core even deeper.

(TO SEE A DIAGRAM OF THE ENTIRE PROCESS: http://www-odp.tamu.edu/publications/tnotes/tn31/mud/fig_04.htm)