Behind the Science – Water on the sea

Of course, I know that there is “water in the sea” but in this post I will tell you something about the fresh water we use onboard.

We are in a two months expedition in the middle of the sea but we take showers, we drink anytime we want, we have a laundry service. We take all of this for granted but the water we use is produced on the ship from the sea water. Here the interview of the Chief Engineer Jack O’Connor our invaluable “water man”.

Q: How many Expeditions have you taken part in?

J: I have lost track of how many Expeditions but I started out on the vessel in May 1987 on Expedition 115

Q: What is your job in the JOIDES Resolution?

J: My job is the Chief Engineer and I am the supervisor for the Maintenance Department on the ship. The Maintenance Departement consist of the ship’s Engineers (4 including myself), Motorman (1), Oiler (2), Welders (2) Mechanics (2 normally but 3 on this expedition), Assistant Mechanic (1) and the Materials Coordinator (1).

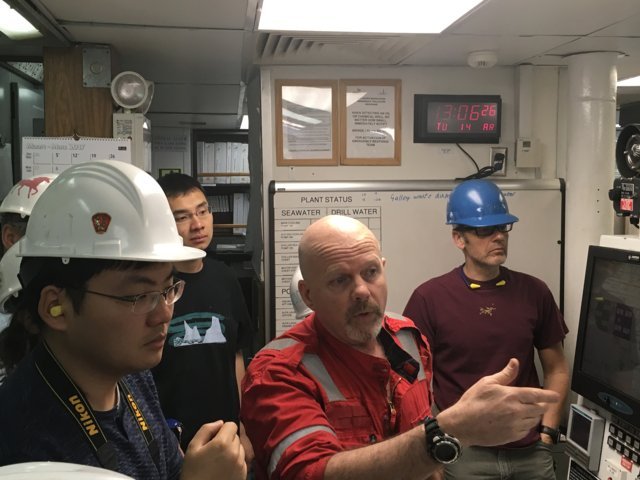

(Ian Barnes first assistant engineer explains us the water system supply)

( Christopher Baquillos, junior oiler and Bimbong Manipor, senior motorman)

Q: How many liters of fresh water do we use in the ship daily?

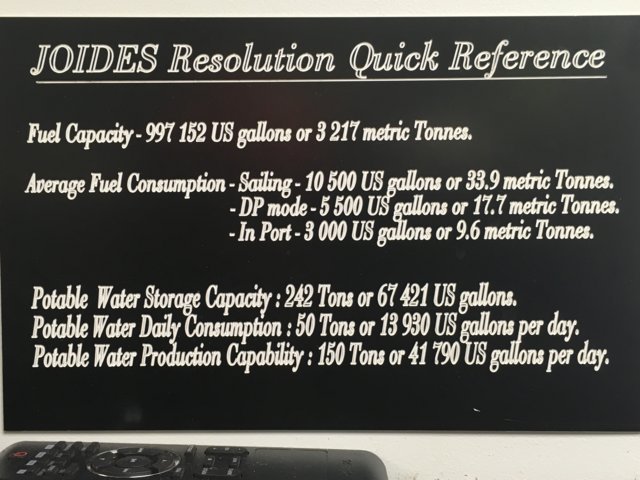

J: Potable water consumption per day can range anywhere from 42185 liters to 52730 per day. There are many things that contribute to the consumption with the largest consumer being the laundry. Potable water is used in the Galley for preparing food, cleaning dishes etc. There are numerous sinks and showers throughout the vessel and within staterooms, cleaning gear lockers, work areas etc which have hot and cold water. The IODP Labs use potable water for all their service and equipment (if required). There are several drinking water fountains around the vessel and finally the toilets all utilize potable water within them.

Q: How do we produce the fresh water in the ship?

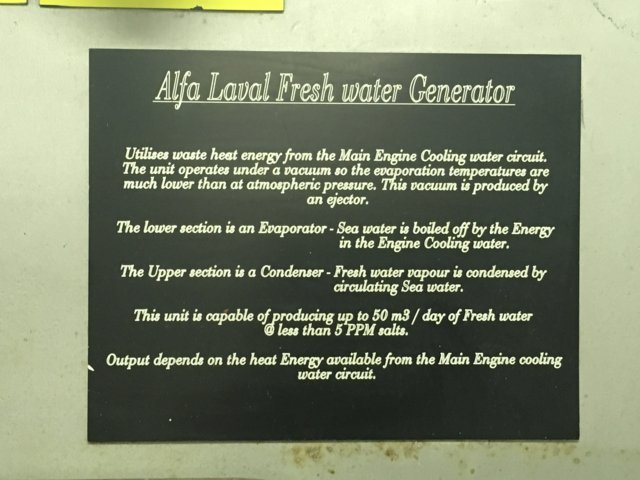

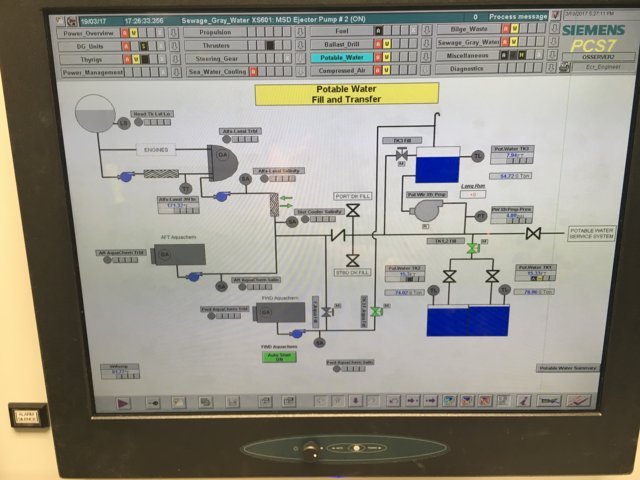

J: Basically we create/produce fresh water by distillation. We bring in sea water and boil it, then cool the steam vapor till ti condenses to fresh water. The excess salts are removed and returned back into the sea. We use a couple of different means to produce fresh water but the principal is the same as previously described. One unit is self-sustained and creates the heat required to bring the sea water to a boil by means of electric heaters. The steam is pulled out of a chamber by means of a compressor where the steam is pumped into a heat exchanger where sea water is used to condense the steak into fresh water while at the same time heating up the sea water to be put onto the main chamber to start the process again. The distillate, (fresh water), that just changed state from a gas to a liquid is still quite hot and that fresh water passes though another heat exchanger to be cooled by sea water before to the storage tanks. The sea water used in this part of the process is circulated in the system and used in the process as noted above. The other two units utilize the same principals but work at much lower temperatures as the units are under a vacuum for the sea water can flash to a gas at 50 degrees C as opposed to 100 degrees C the unit mentioned first. Of these two units one uses waste heat from the engine jacket water as the heat source and the other unit uses electric heaters for its heat source. Between the three units we have on the JOIDES, we are capable of producing 158192 liters of fresh water per day.

Q: How do you check if the water is drinkable?

J: We generate distilled water from our water makers and the distillate that is coming from these units is checked to see how many parts per million of salts are within the distillate produced. Normal range is from 1ppm to 5 ppm, the units alarm once over the 5 ppm range. The ship’s doctor takes water samples every week from various location including the discharge of each of the water makers and performs tests on the sample(s). He also performs the same tests during port calls of water taken from the shore side before we put the water into our tanks or in use. Preliminary results of the tests are immediate but there is a test that requires 24 hours incubation to ensure there is no growths present in the water. We treat the potable water with bromine for sterilization and that is within our storage tanks. Once leaving the storage tanks the water will go through a particle bag filter then through UV Sterilization System then out into the system. Water from the sinks and showers has this process while the water coming from the water fountains and the dispensers in the Galley have an additional carbon filter located at each piece of equipment.