Once in a Blue Moonpool

A few days ago we were lucky enough to test out the Subsea Camera System, which can be attached to the drill string and lowered to the ocean floor. Expedition 356 doesn’t require the camera for drilling, so we performed a seafloor survey looking for corals and reef formation. This was our one chance to see the moonpool open, and the camera in action.

The moonpool is the hole in the bottom of the ship that we lower the drillstring through, and it’s one of the unique features of a drillship like the JOIDES Resolution. Having a big hole (22 ft/6.7m wide) in the bottom of a ship might seem like a pretty bad idea, but it’s perfectly safe, because the walls of the moonpool extend to well above the waterline, so the water can’t get in. The JR is perfectly bouyant and ship-shape, even if that shape is more of a floating doughnut. Usually the moonpool is covered with a metal plate for safety, with a hole just large enough for the drillstring to pass through. But when we need to lower something large, like a re-entry funnel or a camera, the cover is removed, and the view is spectacular.

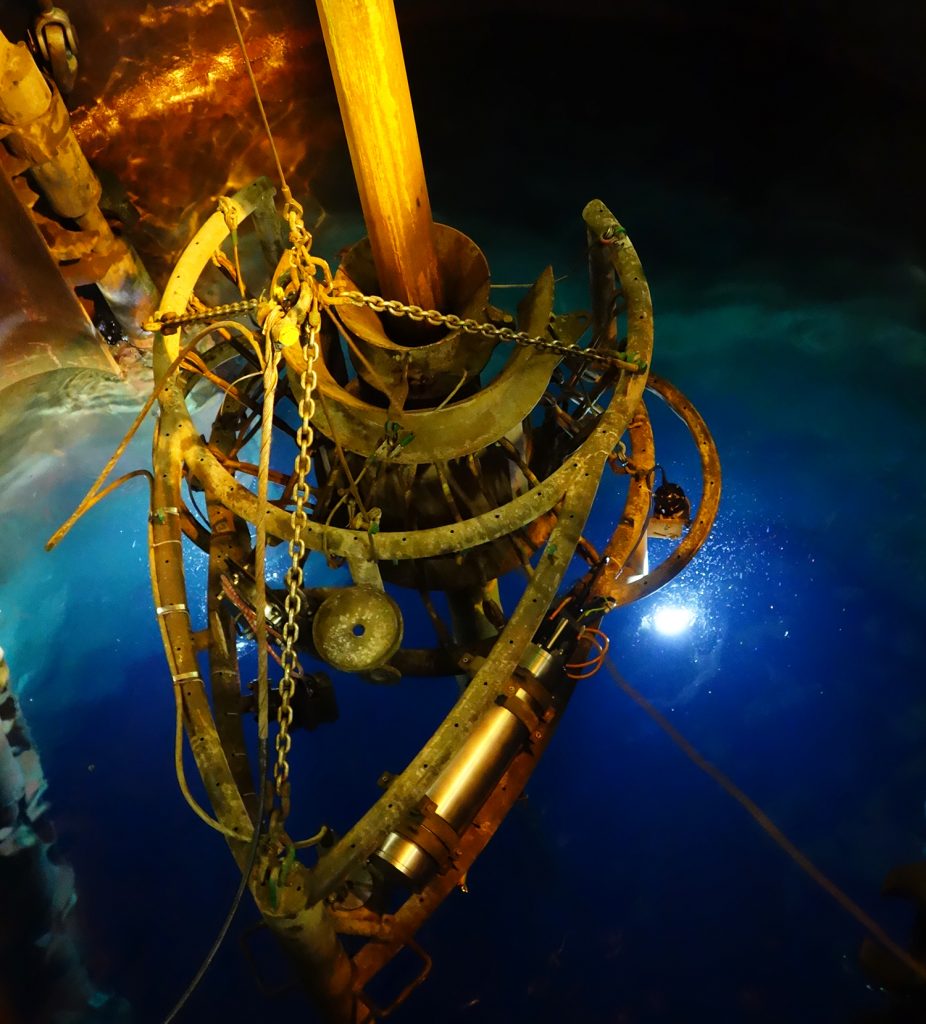

The camera itself is a metal cylinder not much bigger than a loaf of bread, attached to the drillpipe via the Vibration Isolated Transport frame. This frame keeps the camera stable, deadening vibrations and wobbles using rubber bungee cords. The whole camera rig is slowly lowered down the string with a winch, and is remotely controlled by the Dynamic Positioning team, who can move the camera around to get a good view of the seafloor.

As the camera slowly travelled down the drillstring, our scientists crowded around the monitors for a glimpse of fish and sharks, curious or confused by the camera’s bright light. But we don’t have all this equipment just for sightseeing; the camera is vital for when we need to enter the same hole twice.

Expedition 356 is only drilling up to a kilometre deep, mostly through relatively soft sediment, so we can rely on drilling each hole in a single go. But some expeditions drill through solid rock for days at a time, which can wear out even our specialised drillbits. This means that the whole drillstring needs to be pulled up to replace the bit, and then lowered again. But even with the ship’s Dynamic Positioning System, it’s almost impossible to just drop the drill back in that tiny hole. So first they drop a free-fall funnel down the string (a big metal cone, to help guide the drill back into the same hole) and then they use the camera and the ship’s thrusters to carefully guide the drill over the funnel.

This can take HOURS. Lowering the drill string into a funnel only a few metres wide at the bottom of the ocean is like trying to lower a strand of spaghetti into a thimble from the top of a tall building with your eyes closed. It’s an impressive task, and our crew can do it (because they’re the best) but we’re VERY glad it’s not necessary for this expedition!

If you’d like to see a video of the process in action, check out this excellent re-entry from a previous expedition (They hit the cone first time!)

The camera rig is carefully lowered into the moonpool

The drill crew drop a re-entry cone (picture from previous expedition)