Free Children's Books

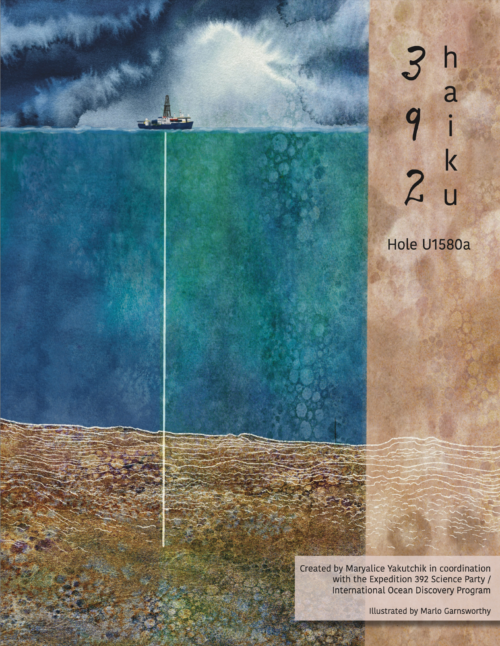

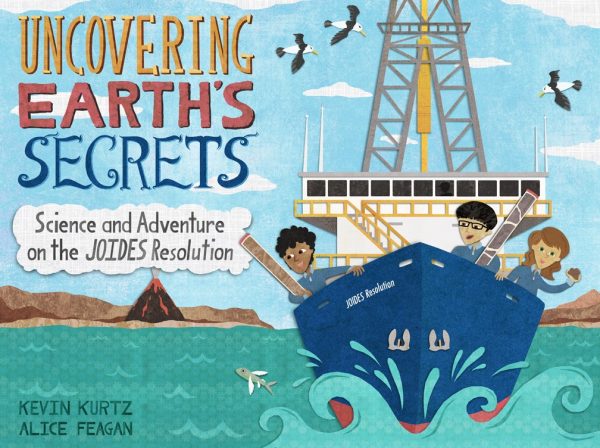

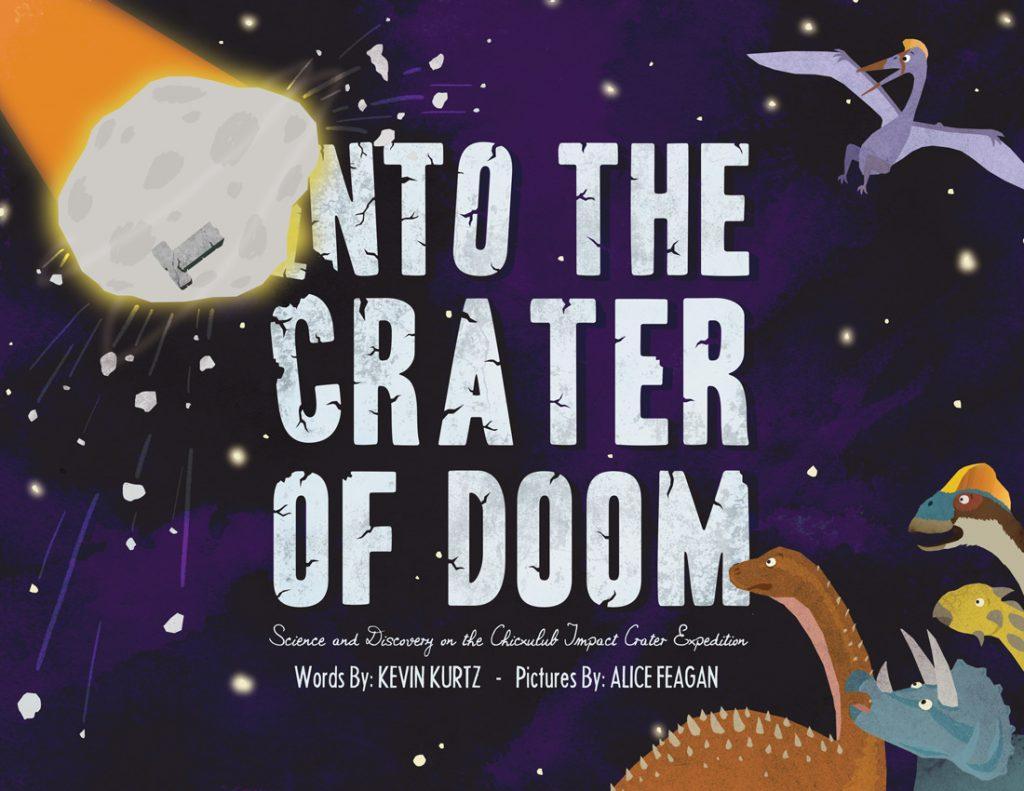

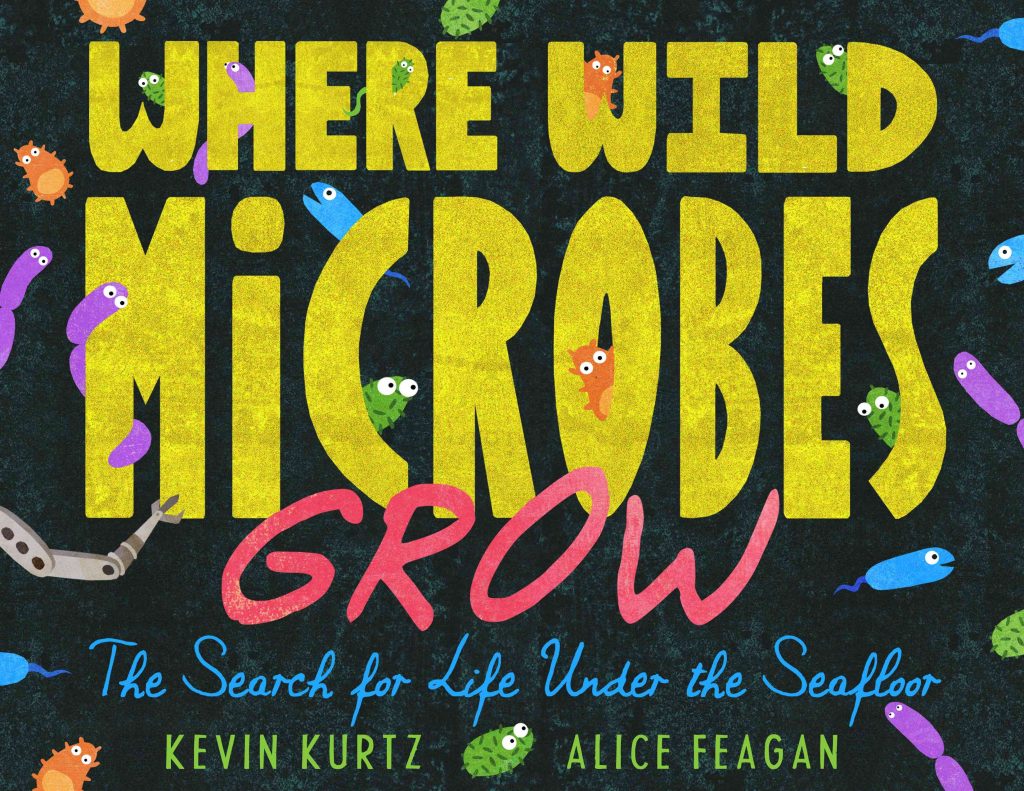

eBooks about the science of the JOIDES Resolution and the International Ocean Discovery Program are available to download for free in both PDF versions that can be viewed on any device and as interactive iBooks that can be viewed on Macs and iPads. Click the covers below to learn more.